AP Electronic Ink Adjustment

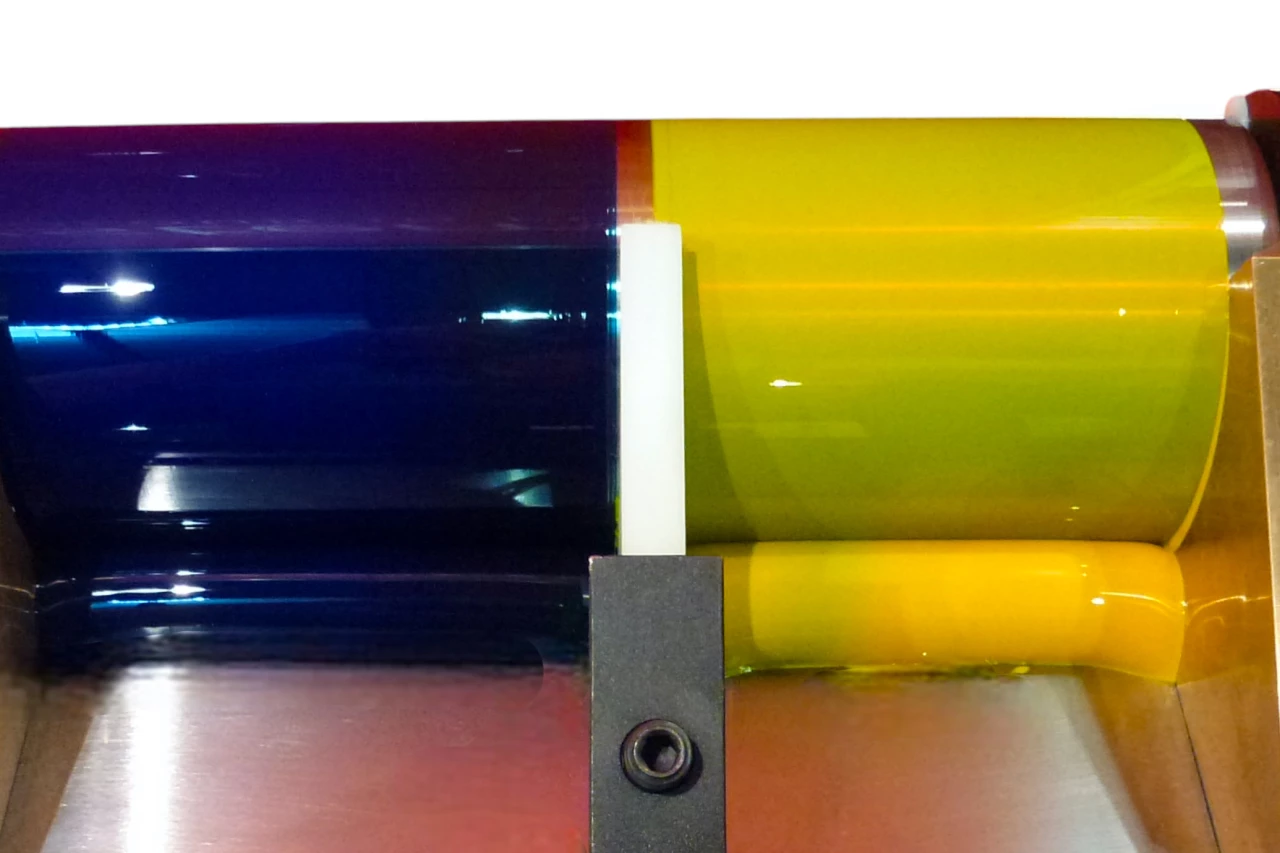

The electronic steered ink duct system (remote control) is used for letter- and offsetpresses of any type. It is also perfectly suitable for retrofittings of older machines. We will find the optimal solution for nearly every kind of printing press (offset or letterpress).