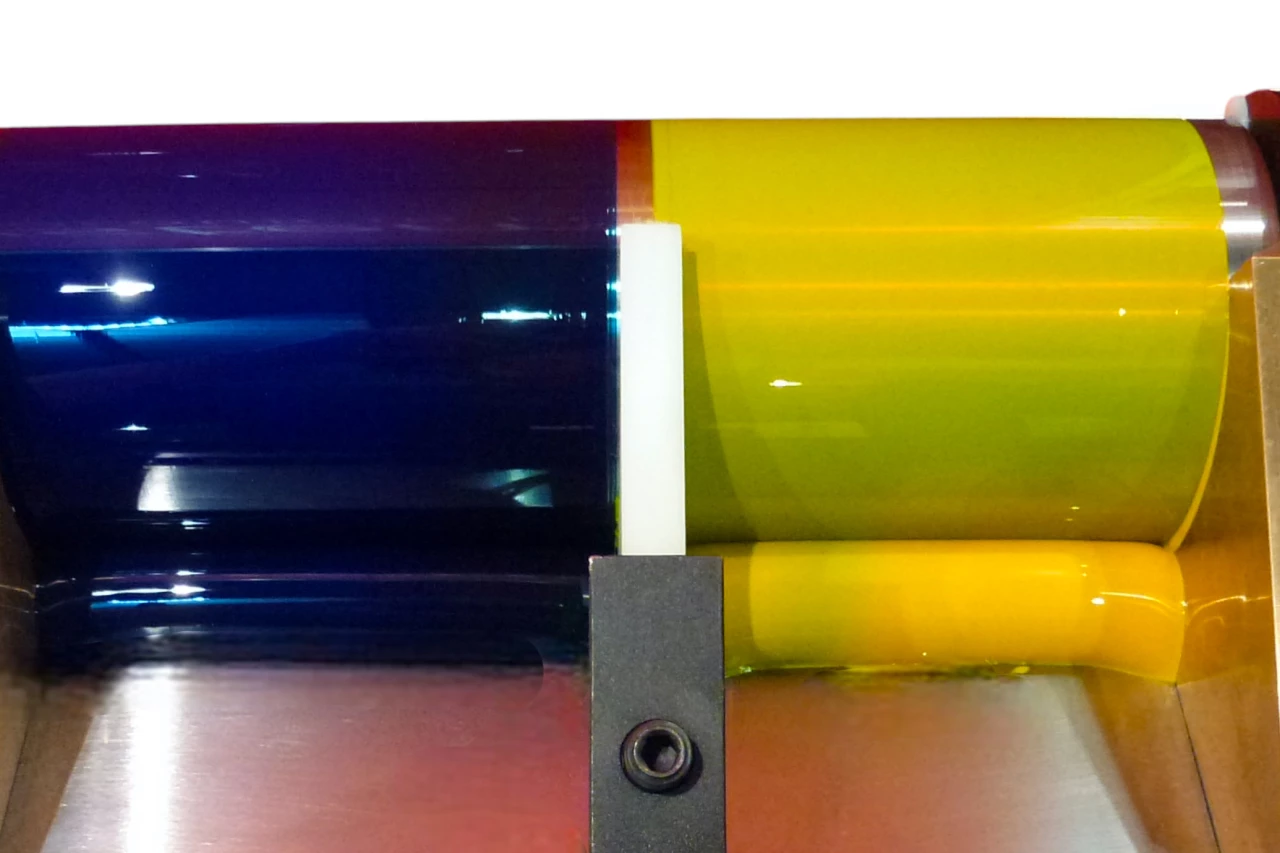

Optimal distribution of colour in the ink fountain

The ink agitator cares for a constant distribution of the colour and passes it towards the duct roll.

Simple installation, also for retrofittings

The system is availeble in different length and models. Type 1: with rotating finger, Type 2: with static finger.

Operation

Movement intervals are controlled by a programmable control.

Technical data

Drive proplusion system: pneumatic cylinder (max. 0.6mPa working pressure)

Adjustable speed: min. 50mm/s, max. 200mm/s

Control unit

Input voltage: 24 VDC +20%-15%

Input current: 6.0 mA

Maximal power consumption: 7.5W