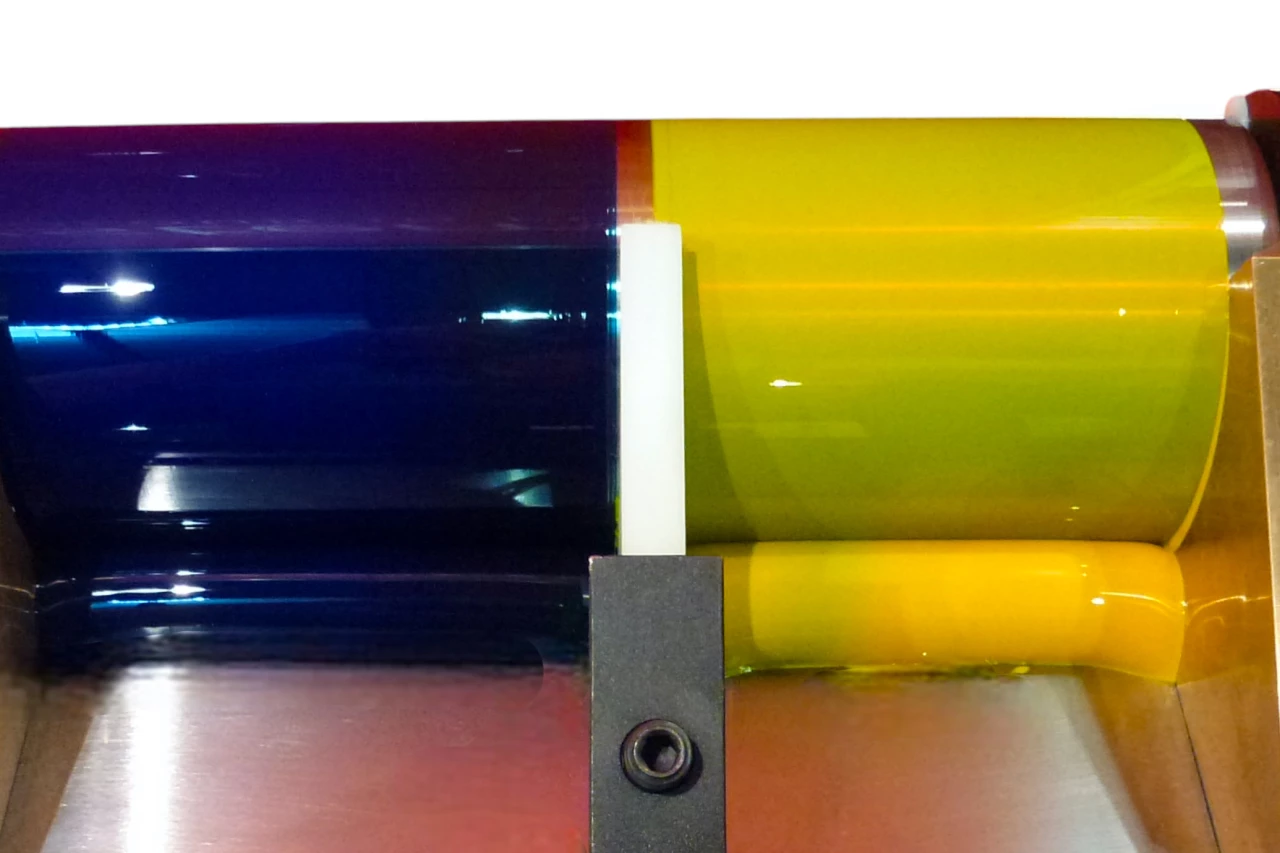

Manual Ink Adjustment

The lever ink duct system suits perfectly to all letter- and offsetpresses. For many printing press brands, it is available as standard solution and ideally suited for retrofitting and modernization of older machines. The function of the systems is independent and allows a suitable solution for nearly every type of machine. We are pleased to give advise!