Your competitive ability in excellence

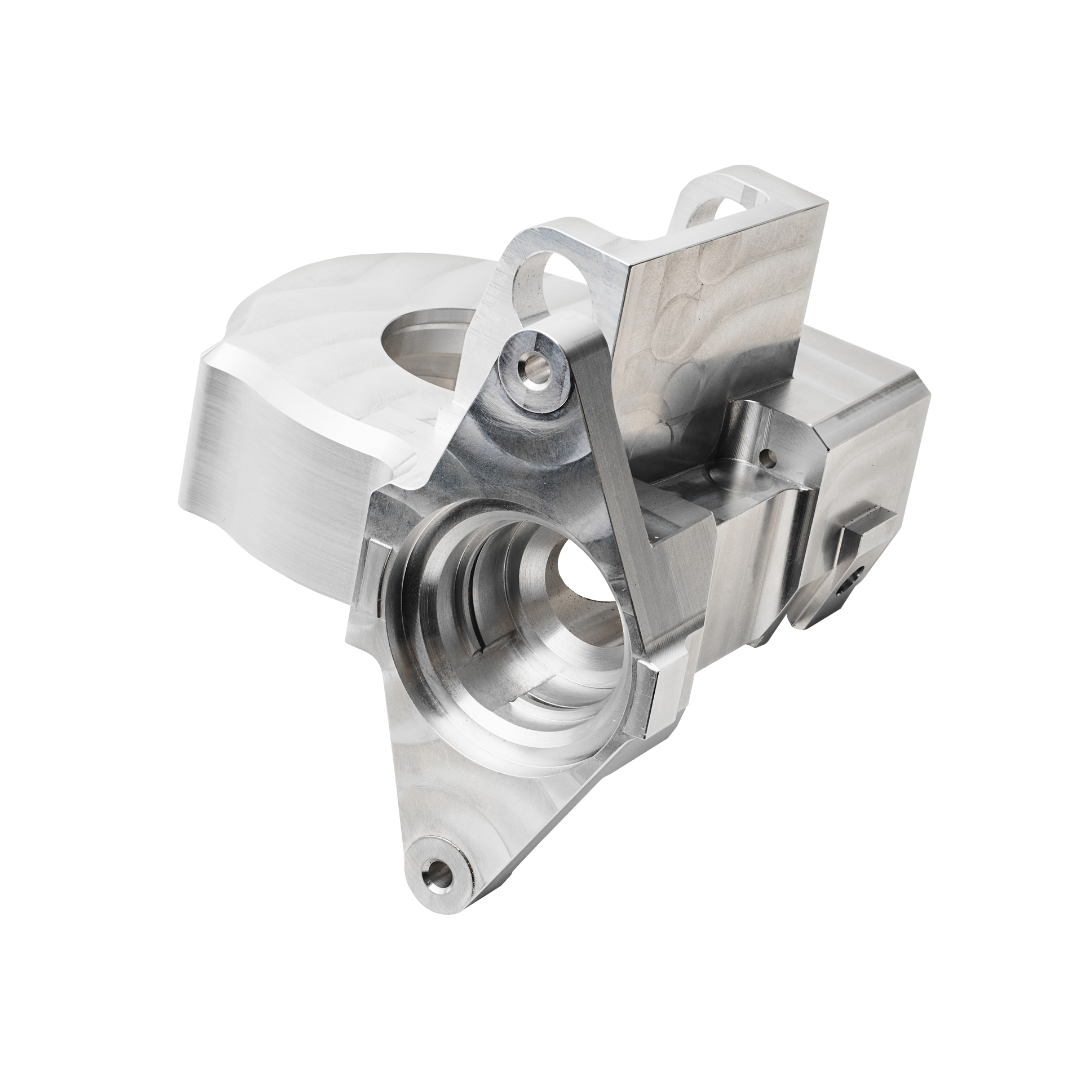

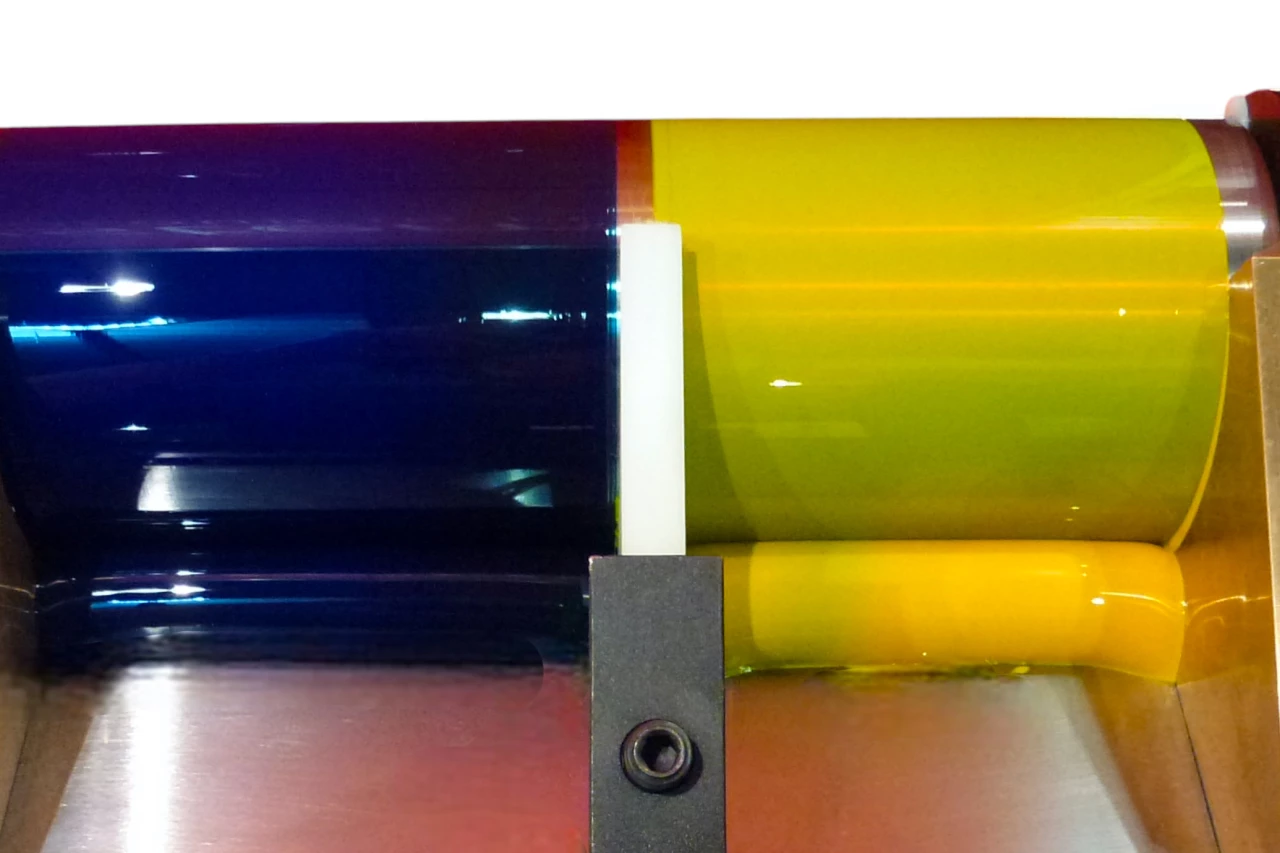

AP Systems is the ideal partner for the development, production and assembly of state-of-the-art ink duct systems for letterpress and offsetpress of all kinds – AP Systems a Brand by hepro.

Our patented solutions are practical and suitable for new printing presses as well as for retrofitting and modernizing book and offset printing presses from all manufacturers.

For each machine type a solution

Well-known printing machine manufacturer serve? Our products by default or offer them as an option. Existing machines are easily retrofitted. Due to the modular applications, we are able to put special-purpose solutions quickly and cost-efficiently into practice.

At the following machinge brands, we did retrofittings successfully:

Heidelberg, Gallus, Goebel, Iwasaki, Ilma, Akira, Labelmen, Müller Martini, Drent, Sanjo and many more

.png)